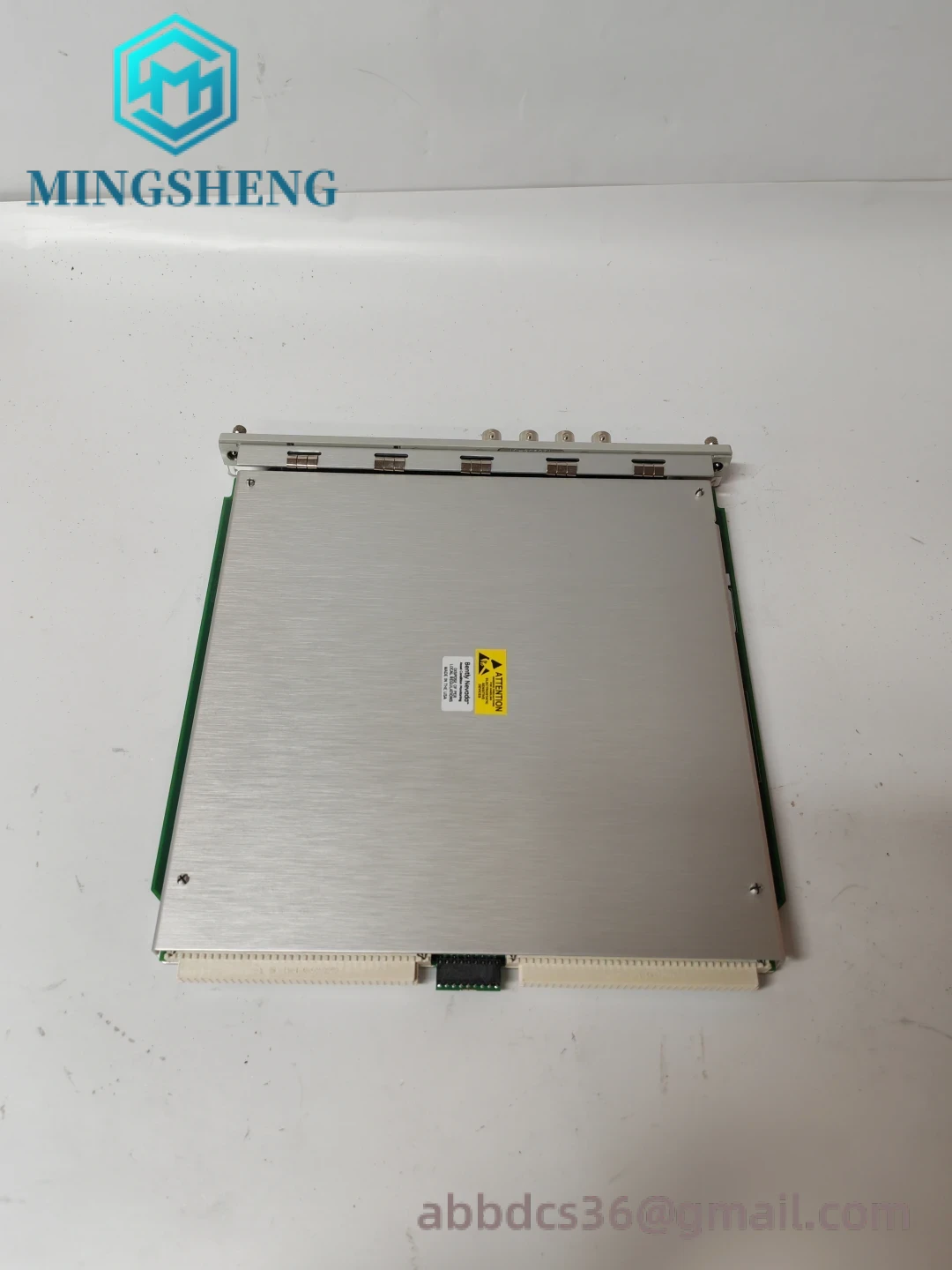

Bently Nevada 350077M 176449-07 Vibration Monitoring Module

Engineered for precision diagnostics in critical machinery environments, this module serves as the backbone for vibration protection systems across turbines, compressors, and industrial rotating equipment. Its real-time monitoring capabilities help prevent catastrophic failures through advanced signal analysis and programmable alarm thresholds.

| Manufacturer | Bently Nevada |

| Model Number | 350077M 176449-07 |

| Input Signal | Velocity/Acceleration Sensor Interface |

| Output Signals | Analog (4-20mA) & Digital (Relay Contacts) |

| Operating Voltage | 24 VDC ±15% |

| Certifications | CE, UL 508, ATEX Zone 2 |

| Mounting | 35mm DIN Rail (EN 50022) |

| Operating Temp | -25°C to +70°C |

In practical deployments, this module has proven invaluable for power generation plants monitoring steam turbine vibrations and offshore platforms protecting critical compressors. The integrated Modbus RTU interface allows seamless integration with SCADA systems, while the built-in event logger provides detailed fault analysis records. We’ve seen customers reduce unplanned downtime by 40% after implementing this solution in their predictive maintenance strategy.

Our inventory includes complementary Bently Nevada systems like the 3500/22M rack interface module and 3500/42M proximity monitor. We maintain global stock across 16 regional warehouses, ensuring 48-hour delivery for most standard configurations. Technical support specialists are available to assist with configuration through the 3500 Rack Configuration Software.

Why Choose Our Industrial Automation Solutions?

- One-year comprehensive warranty with free technical support

- Global inventory network with 6 strategic warehouse locations

- Factory-tested components with full traceability documentation

- Custom configuration services for complex system integrations

For current pricing and availability, please contact our sales team via:

“After implementing Bently Nevada’s 3500 system with components from this supplier, our offshore maintenance team reduced turbine downtime by 6 weeks annually. The technical support during configuration was particularly valuable.” – Senior Engineer, Oil & Gas Sector

There are no reviews yet.