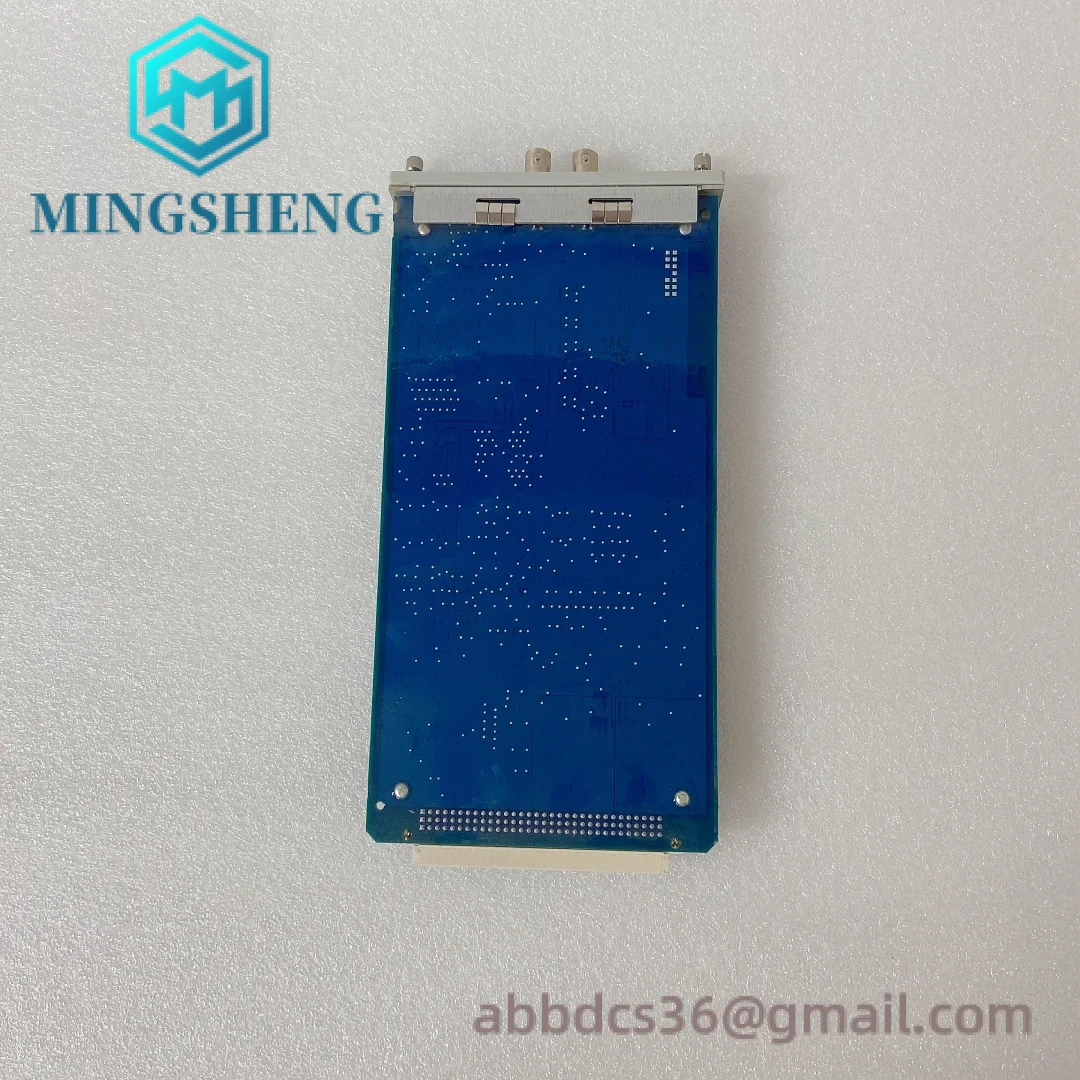

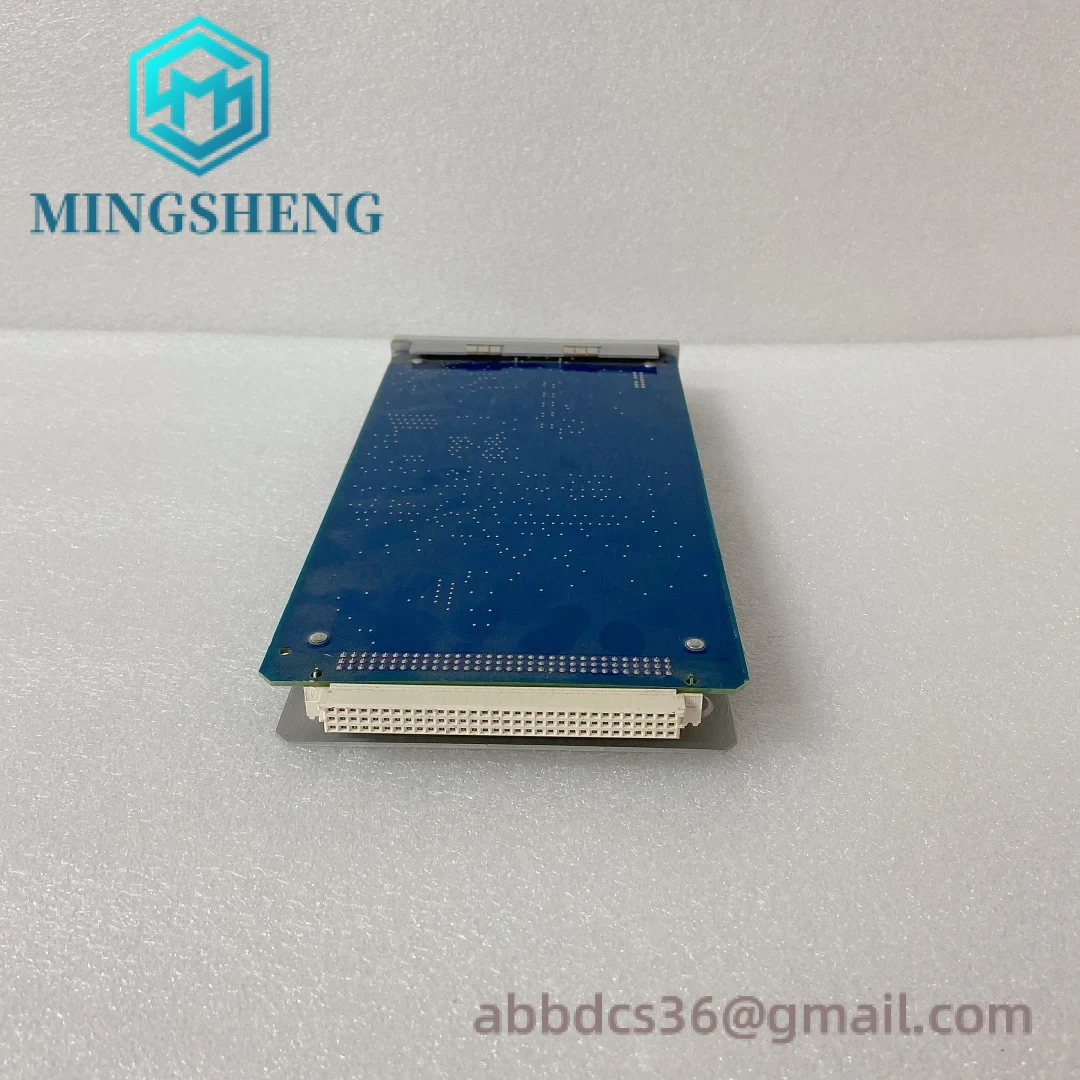

Bently Nevada 3500/25 184684-01 Vibration Monitoring Module

Used in critical machinery protection systems across industries like power generation and oil & gas, this module continuously analyzes vibration levels in turbines, compressors, and pumps. Its dual-channel monitoring detects early mechanical faults through proximity probes, velocity transducers, or accelerometers – think of it as a diagnostic tool that prevents catastrophic failures before they happen.

| Brand | Bently Nevada |

|---|---|

| Model | 3500/25 184684-01 |

| Channels | 2 Input Channels |

| Outputs | 4-20mA + Alarm Relays |

| Voltage | 24 VDC |

| Protocol | Modbus RTU |

| Mounting | DIN Rail |

| Weight | 0.5 kg |

Real-World Applications

We’ve deployed this module in environments ranging from offshore drilling platforms to coal-fired power plants. One customer in Texas mentioned how it caught bearing wear in a gas turbine 48 hours before scheduled maintenance – that’s the difference between a planned repair and a $50k emergency shutdown.

Our inventory includes compatible Bently Nevada components like the 3500/22M, 3500/32, and 1900/27 systems. Most customers pair this module with Proximitor probes for shaft vibration monitoring, though we’ve seen creative uses in gear box diagnostics too.

Why Choose Our Service

With 16 regional warehouses across 6 countries, we typically ship within 24 hours of order confirmation. Our 1-year quality guarantee covers both new and refurbished units – I’ve personally handled replacements for modules that failed after 14 months due to extreme vibration environments.

For specific pricing, send us a message via WhatsApp or email abbocs36@gmail.com. Include your location and preferred delivery method – we’ll provide exact lead times based on your region.

ABBOKOK Industrial Automation Parts Co., Ltd. | 16 Global Warehouses | 1-Year Quality Guarantee

Stocking 3500/25 modules alongside complementary brands like GE, Triconex, and Foxboro

There are no reviews yet.