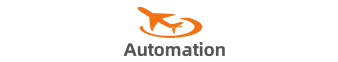

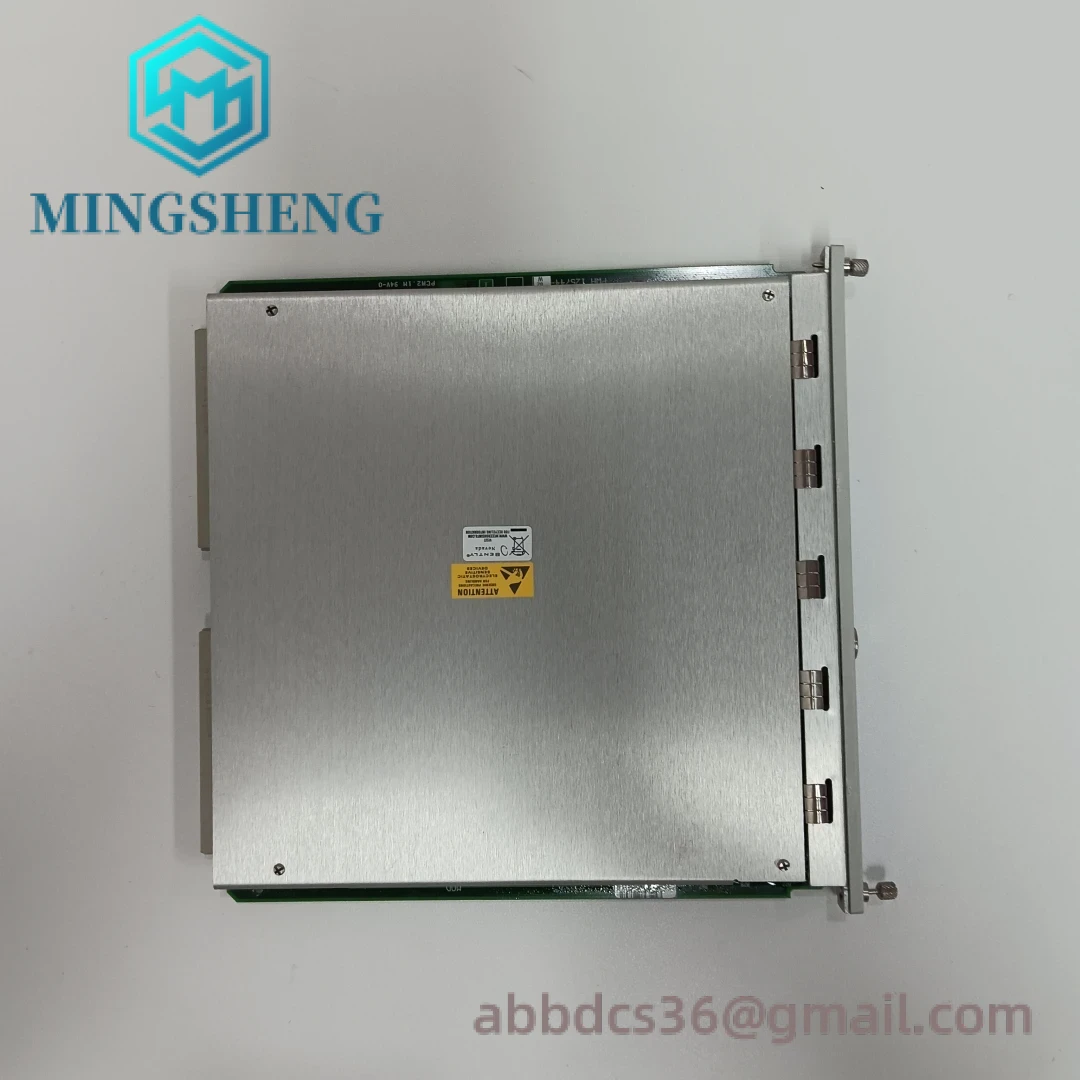

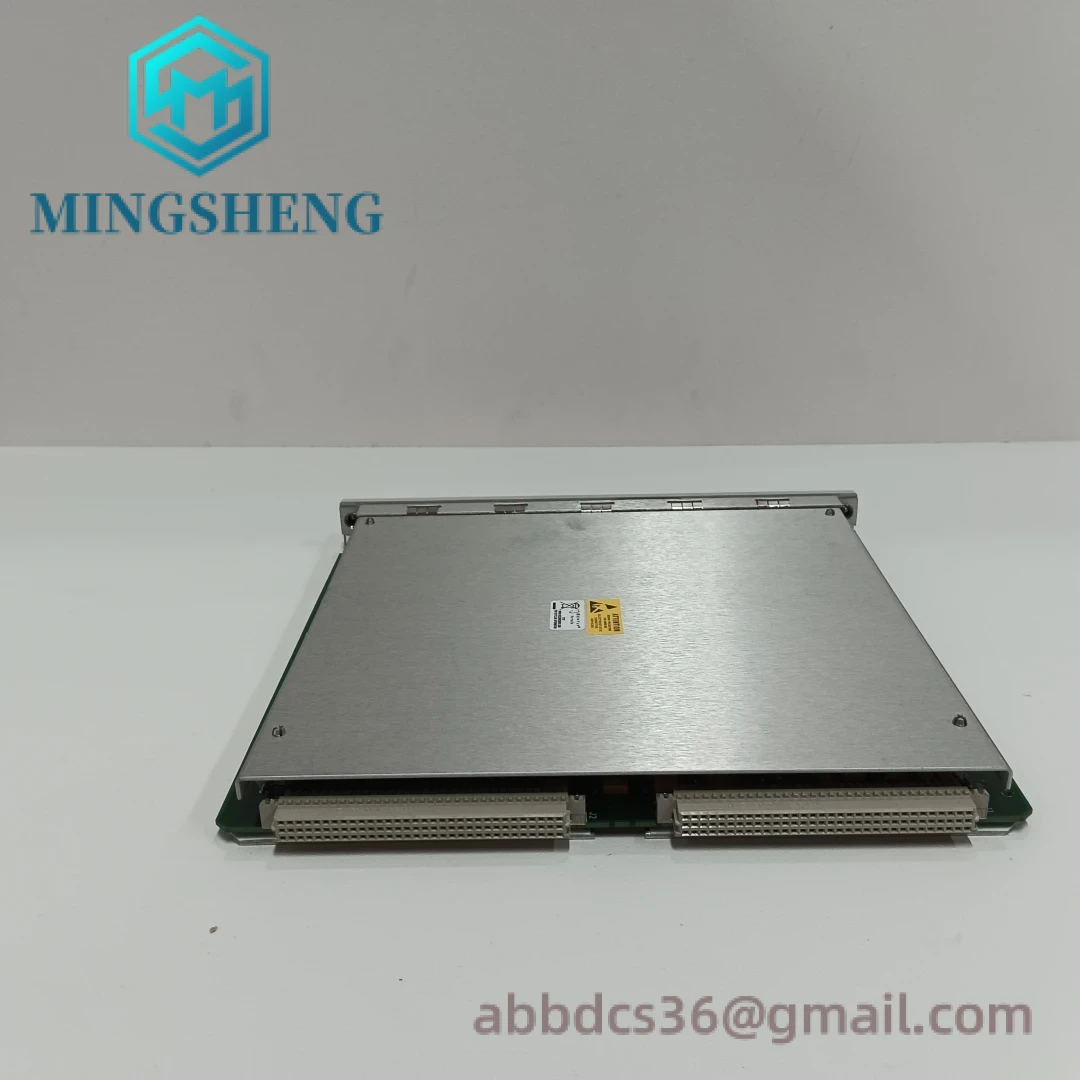

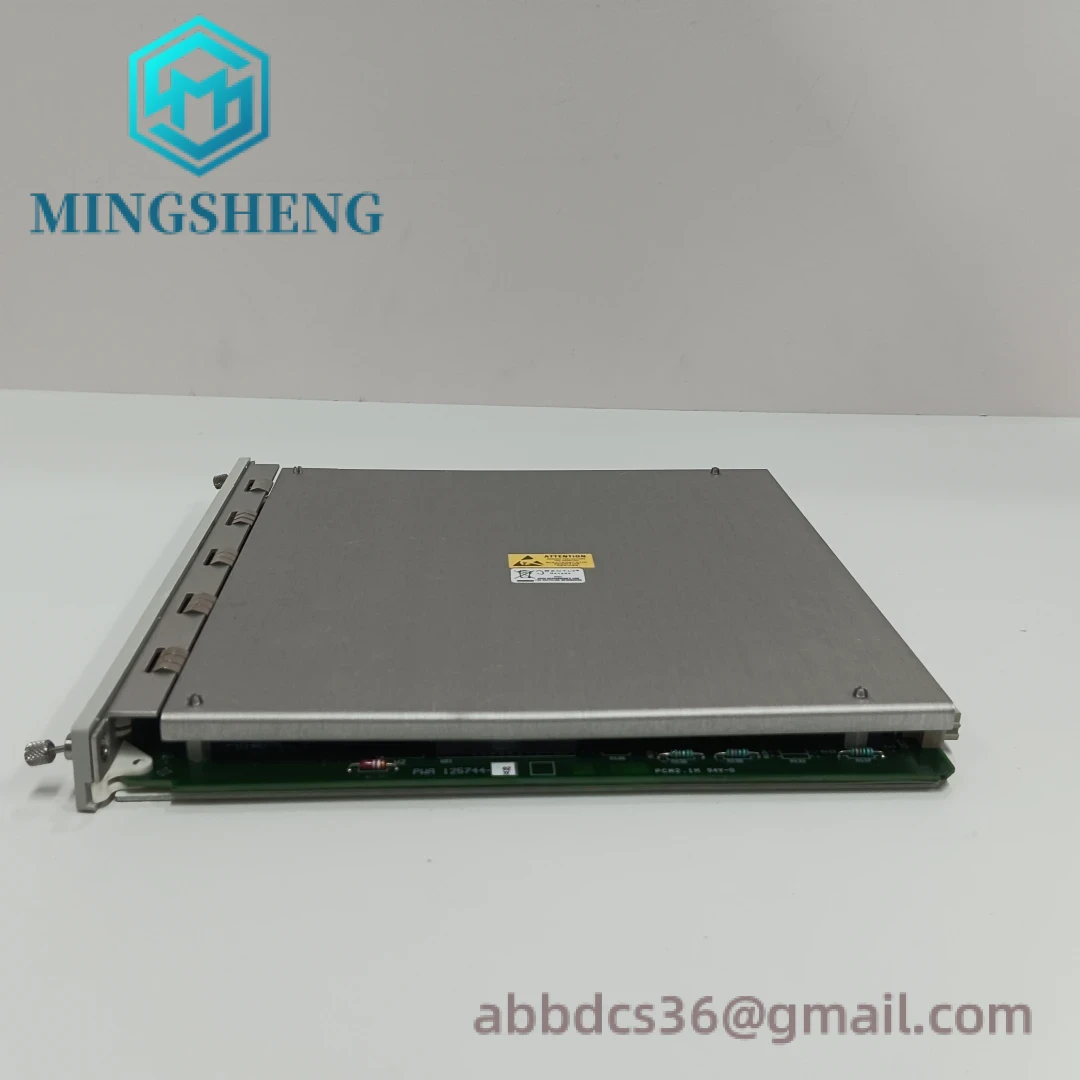

Bently Nevada 3500/20-01-02-00 Vibration Monitoring Module

This high-precision vibration monitoring module serves as critical protection for industrial rotating equipment. Designed for continuous condition monitoring of turbines, compressors, and pumps, it delivers real-time vibration analysis to prevent catastrophic failures and optimize maintenance scheduling. Unlike basic vibration sensors, this module combines advanced signal processing with industrial-grade durability.

| Brand | Bently Nevada |

|---|---|

| Series | 3500 |

| Channels | 4 |

| Measurement Range | 0-100 mils p-p |

| Output Signals | 4-20mA + Modbus |

| Housing | Aluminum Alloy |

Real-World Applications

We’ve seen this module excel in demanding environments like offshore oil platforms where vibration monitoring prevents turbine failures, and in chemical plants where early bearing wear detection saves millions in downtime costs. The 3500/20 integrates seamlessly with legacy systems while supporting modern Ethernet/IP communication protocols.

Our inventory includes complementary Bently Nevada 3500 series modules like the 3500/22M displacement monitor and 3500/32 relay module, plus interface components for complete system solutions. For specialized needs, we also maintain stock of 1900/27 proximity probes and 3500/15 vibration switches.

Our Service Commitment

With 16 global warehouses and 18 years of industrial automation experience, we guarantee 1-year warranty on all Bently Nevada products. Our team handles urgent replacement needs through 24/7 technical support, and maintains cross-reference databases for obsolete module replacements.

Need pricing for your specific requirements? WhatsApp our engineering team directly or email abbcdcs36@gmail.com for current stock availability and technical specifications.

There are no reviews yet.