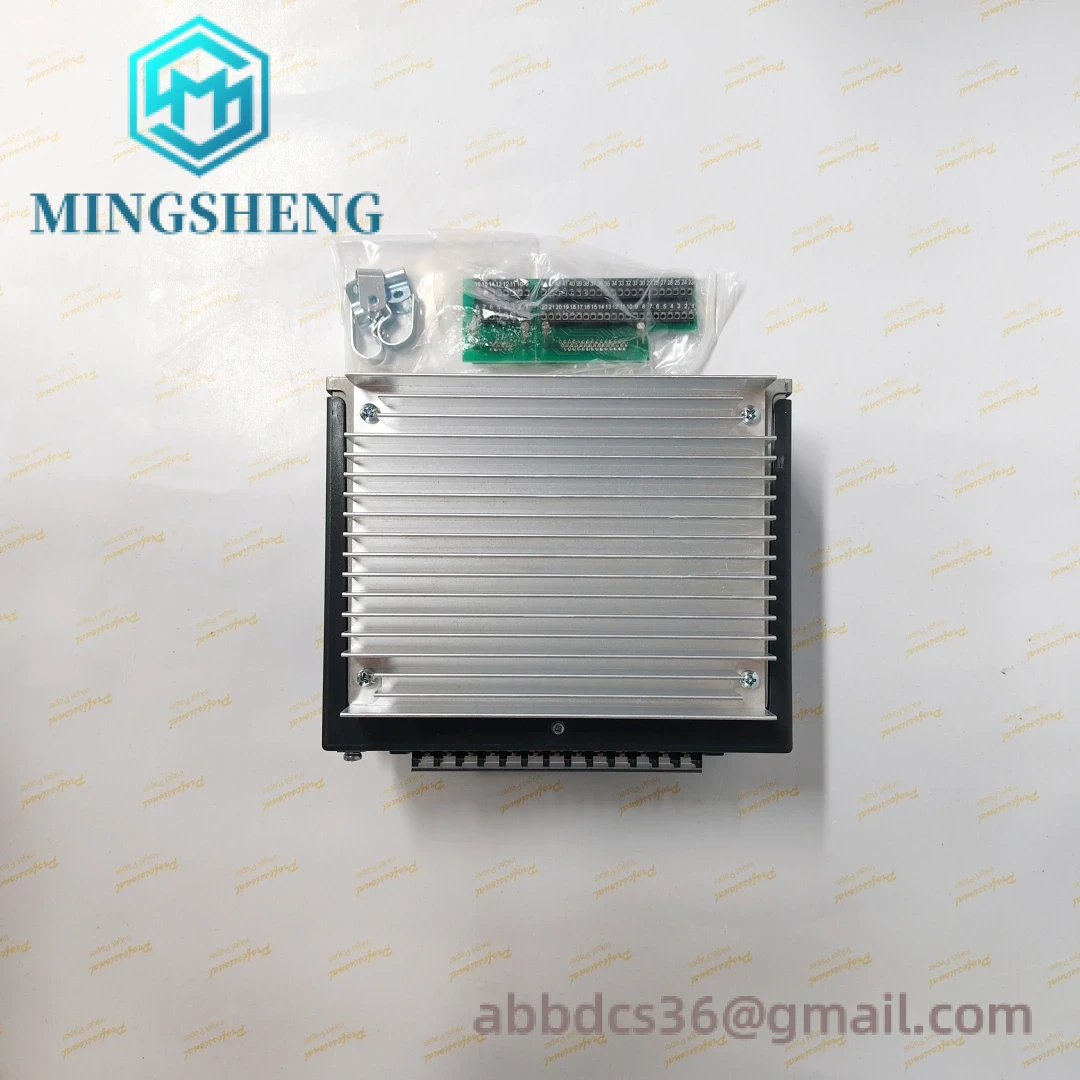

AB PC834-001-T Industrial Control Module

Engineered for precision automation tasks, the Allen-Bradley PC834-001-T Industrial Control Module delivers rock-solid performance in harsh industrial environments. This compact 24VDC module shines in applications requiring exact process control—think motor synchronization in packaging lines, valve actuation in chemical plants, or conveyor belt coordination in logistics hubs. Its dual Ethernet/IP and RS-485 interfaces make it a communication workhorse for integrating legacy systems with modern PLC architectures.

Technical Specifications

| Specification | Details |

|---|---|

| Manufacturer | Allen-Bradley (Rockwell Automation) |

| Series | PC834 |

| Output Configuration | 8 x 2A Transistor Outputs |

| Communication | Ethernet/IP + RS-485 |

| Environmental Range | -20°C to +65°C Operating Temp |

| Certifications | CE, UL, cUL |

| Physical Dimensions | 120 x 75 x 45 mm (4.7″ x 3″ x 1.8″) |

Figure 1: Module front panel showing terminal block arrangement and LED status indicators

Real-World Applications

This module excels where reliability meets complexity. A Midwest automotive plant recently deployed it for robotic welding cell coordination, leveraging its precise 2A outputs to control solenoid valves with ±0.5ms timing accuracy. In another case, a pharmaceutical manufacturer used its RS-485 interface to bridge legacy batch controllers with their new Logix 1756 system—cutting integration time by 40%.

Common deployment scenarios include:

- High-speed packaging line control

- Multi-axis motion control systems

- Hybrid PLC-DCS architectures

- Oil & gas field instrumentation networks

Works seamlessly with Allen-Bradley’s 1756-L7x controllers and 2711-K series HMIs. We frequently ship this module alongside 1794-IB16 input cards for mixed I/O architectures.

Why Partner With Us

With 19 years in industrial automation spares (since 2005!), we’ve built a global network of 16 regional warehouses to ensure 98% same-day dispatch rates. Every PC834-001-T ships with our 1-year functional warranty—no questions asked. Last quarter alone, we supported 32 urgent retrofits across energy, automotive, and food processing sectors.

Need immediate support? Our engineers typically respond to technical inquiries within 2 hours during business hours. Stock check this part using our real-time inventory portal or contact us directly:

Figure 2: Module installed in a typical 19″ control cabinet setup with complementary AB hardware

*Note: While we maintain 98.7% stock accuracy across our 15,000+ SKUs, some legacy modules may require core exchange programs. Current build-to-order lead times for new units are 8-10 weeks as of Q3 2023.

There are no reviews yet.